The laboratory

The temple of research and development, the place where science meets human knowledge.

Continuous investments and controls to offer customised and targeted solutions to our customers. Supported by technology and technical-scientific expertise, we monitor every stage of the cork production chain from raw material to finished product.

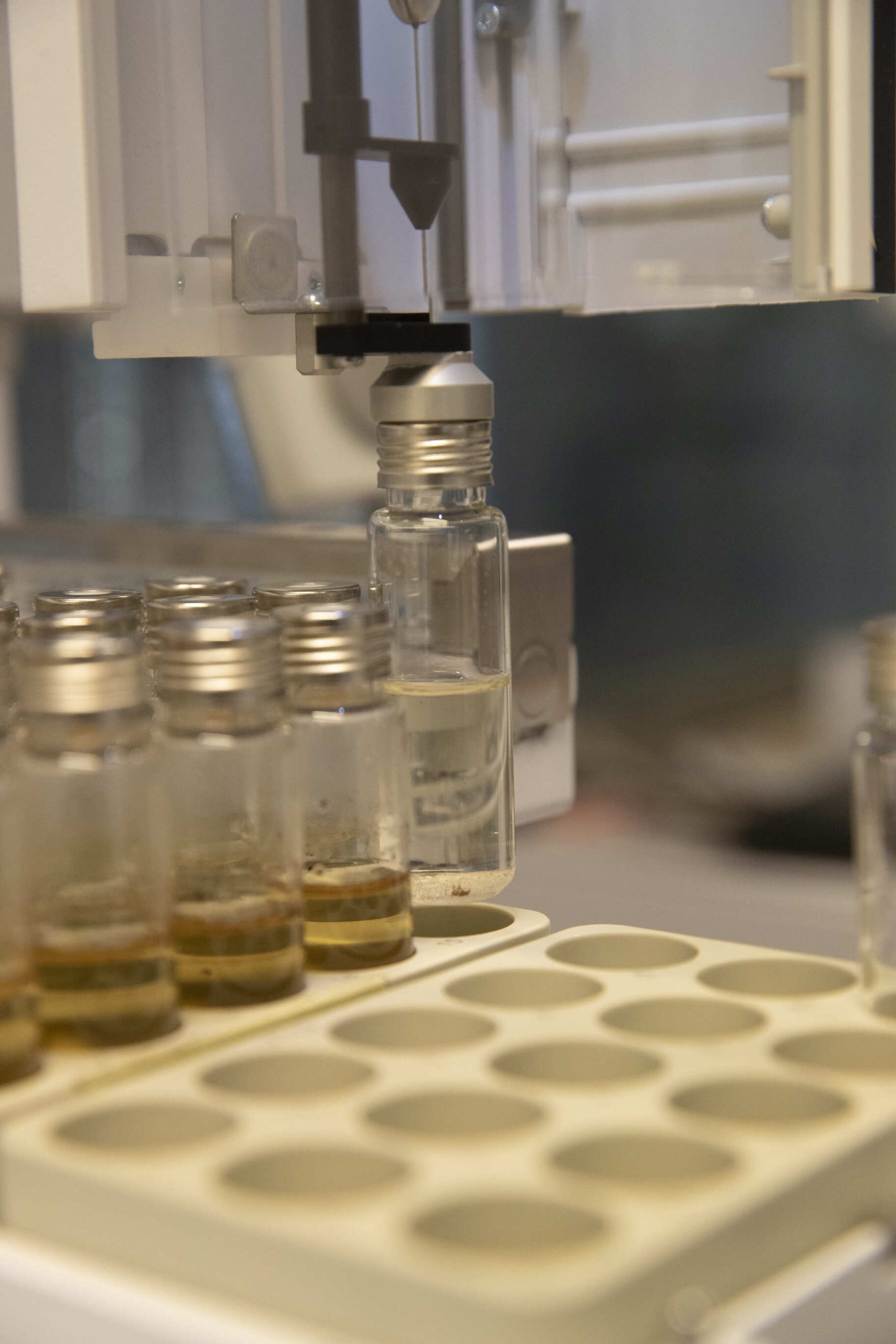

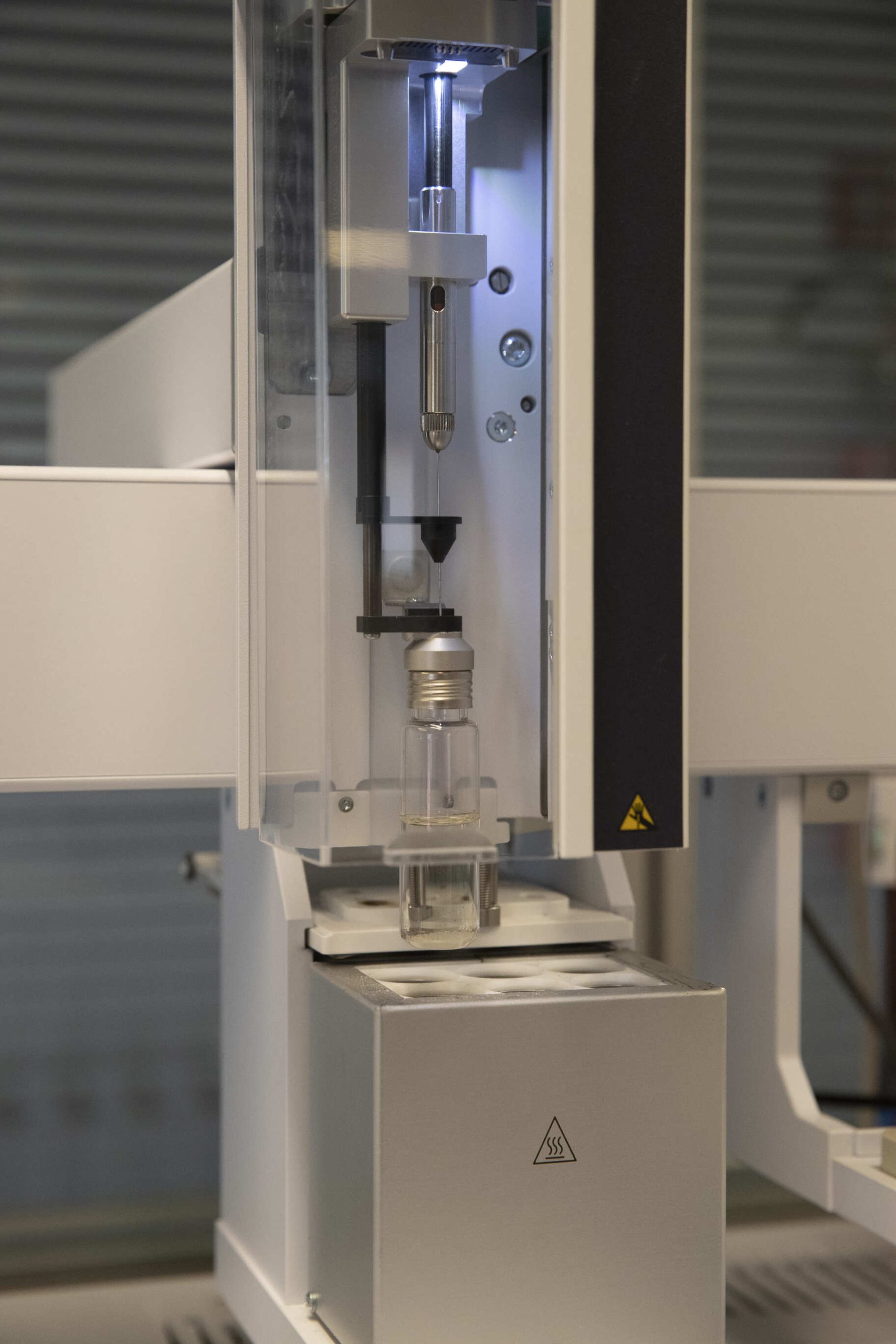

The instrumental analyses allow to determine and quantify any pollutant compounds releasable in a solution, an analysis performed using gas chromatography and mass spectrometry techniques, with solid phase extraction technique (SPME).

Very high instrumental sensitivity to detect even minute variations in abnormal transfers in wine and intercept any non-compliant batches.

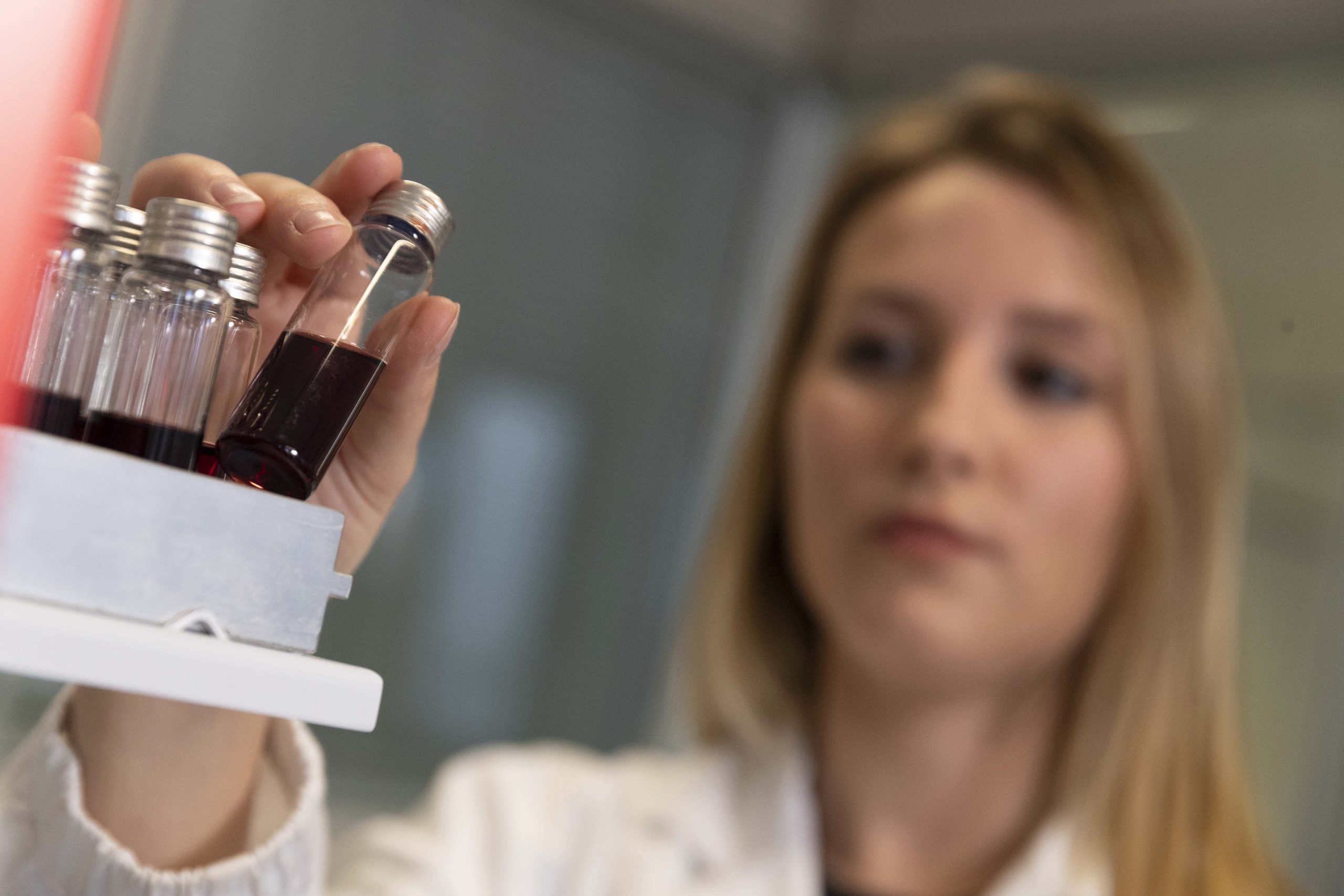

Our sensory analysts ensure the suitability of the products tested by bringing samples into contact with extracting solutions under critical conditions, guaranteeing a final product totally free of sensory defects.

The entire process is carried out using official methods and specific protocols, to always meet our customers’ needs.

To ensure compliance with the strictest domestic and international reference standards, each cork stopper is tested to assess its chemical, physical and mechanical uniformity using specific technologies and established methodologies.

Various parameters, such as the content of oxidising residues from washing, dimensional characteristics, breaking load resistances, liquid and gas sealing, content of releasable dust and turbidimetric analysis, moisture content, extraction, compression and recovery forces are systematically and extensively monitored.

A strict system for risk analysis at critical points (HACCP) is implemented at every stage of the production chain, from the forest to the finished product. Microbiological tests on finished cork stoppers are necessary to ensure the quality of the cork in the bottle and the necessary compliance with the industrial standards in force.

We are committed to the highest standards of quality, transparency and sustainability. Our aim is to guarantee safe and sensory-perfect cork stoppers, produced within a fully certified supply chain.

Production site

Località Ignazioni, 07023

Calangianus (SS), Sardegna – Italia

Legal head office

Via Belvedere 60, Località Macia

37040 Arcole (VR), Veneto – Italia